What We Are

OEM Remanufacturing Service Center

What is an OEM Remanufacturing Service Center?

Spanning industries from automotive, to electronics, utilities, and all types of manufacturing, remanufacturing is a key part of product lifecycle management (PLM). Original Equipment Manufacturers (OEM) use remanufacturing service centers to extend the life of their products, parts and components.

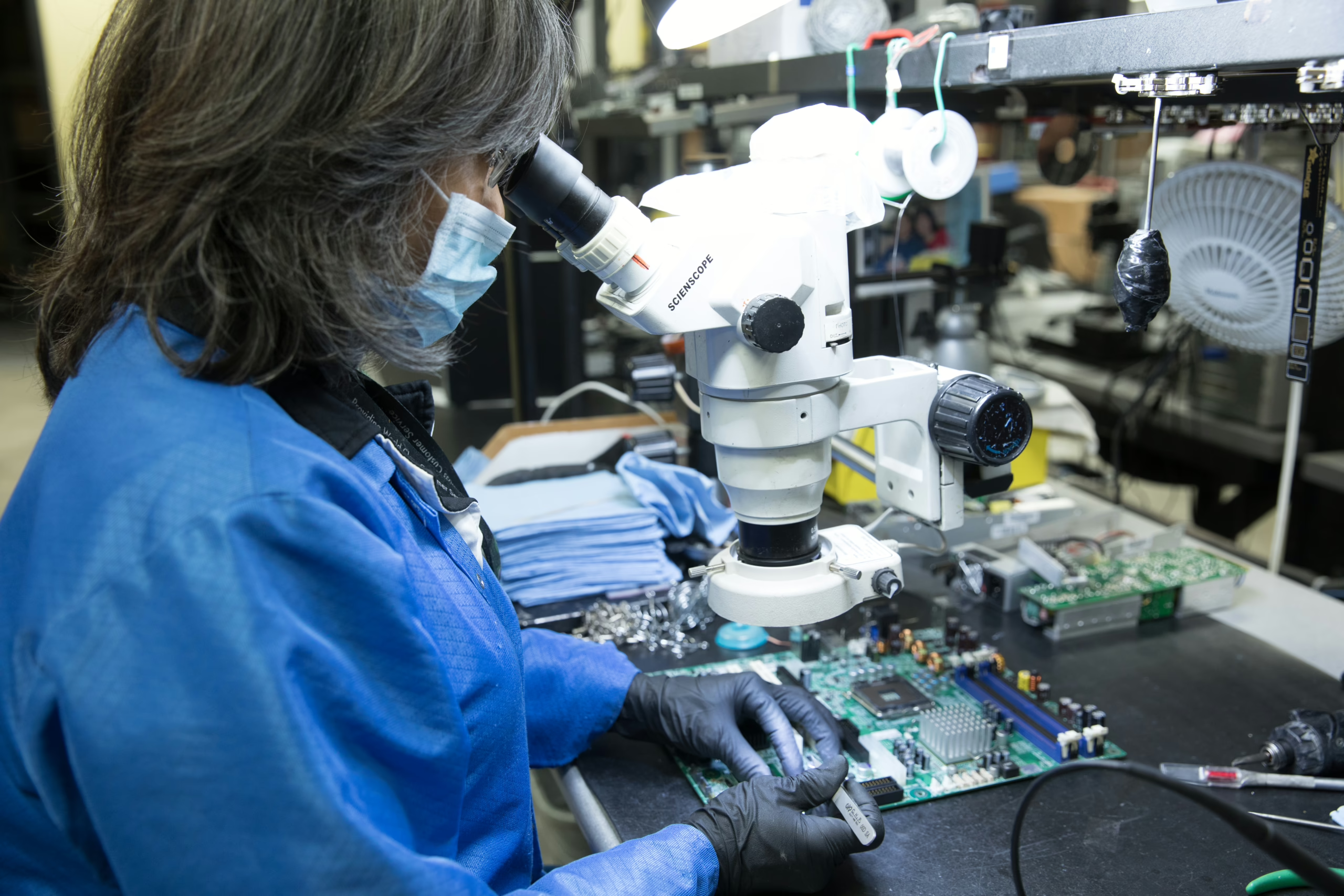

An OEM remanufacturing service center usually has an onsite team of technicians working to test and repair, as well as massive warehouse space for maintaining inventories. Another key component of a remanufacturing service center, especially in the field of automotive electronics, a knowledgeable customer service team that can not only take orders for remanufactured parts, but also advise parts dealers and others who call in on the best course of action when necessary. In addition, most OEM remanufacturing service centers have intricate logistics and shipping capabilities that can get remanufactured parts where they need to go efficiently.

Why Do OEMs Use Remanufacturing Service Centers?

OEMs must focus on their main enterprise – manufacturing original equipment. Working with a remanufacturing service center helps to offload the responsibility of repair, and keep the business focused on innovation, efficiency, and profit.

OEMs outsource rebuilding, refurbishing and repair to remanufacturing service centers that specialize in such activities, because one company cannot be expected to do every single thing in its vertical. This allows OEMs to nurture the best parts of their profit centers while managing PLM through a trusted OEM remanufacturing service center partner. When it’s possible to engage a customized remanufacturing program, OEMs see even more benefits.

Focus on Innovation | Improve Efficiency | Drive Profit

Automotive Remanufacturing Service Center Consolidation

Overnight and next day shipping became a reality in the late 1990s for the automotive parts industry. That meant a big shake up in the way OEMs and automakers work with service centers. Previously, OEMs and automakers relied on a geographically diverse network of remanufacturing service centers in order to meet demand quickly for physically dispersed buyers.

When next day shipping made it feasible, OEMs began consolidating their service center networks.

Read our Case Study on how AER was chosen as Ford’s remanufacturing service center amidst consolidation.

ebook

More than 60 years in the remanufacturing business has taught us exactly what it takes to keep up with the latest technologies and operations standards. We pride ourselves on running a state-of-the-art remanufacturing facility ready to take on the challenges of autonomous vehicles and the green future.